Metalmac

Friday, 5 March 2021

test form

Sunday, 14 February 2021

Blacktown Metal Fabrication Expert

Most people don’t know who to call when it comes to custom engineering projects around the home or commercial space. With such a diverse variety of jobs and tasks, custom metal fabrication expert David McNeice really enjoys the fact that no two jobs are the same and presents it only unique challenges.

Based In Blacktown NSW, David has forged a career helping everyone from metal engineering for large scale industrial facilities to regular domestic custom metal-work projects. Some of Davids skill-sets include, custom welding, garage storage racks, trailer and caravan modifications, fences and security gates, customs jigs, machining, cutting, bending, shaping… You name it, we can probably do it!

There really is no limit to the type of projects we tackle here at Metalmac, except to say we specialize in small to mid size custom metal engineering projects, and we are not involved with large scale structural engineering projects. Domestic, Commercial and Industrial clients are our sweet-spot and we love the challenge of solving your engineering problems with creative and efficient solutions.

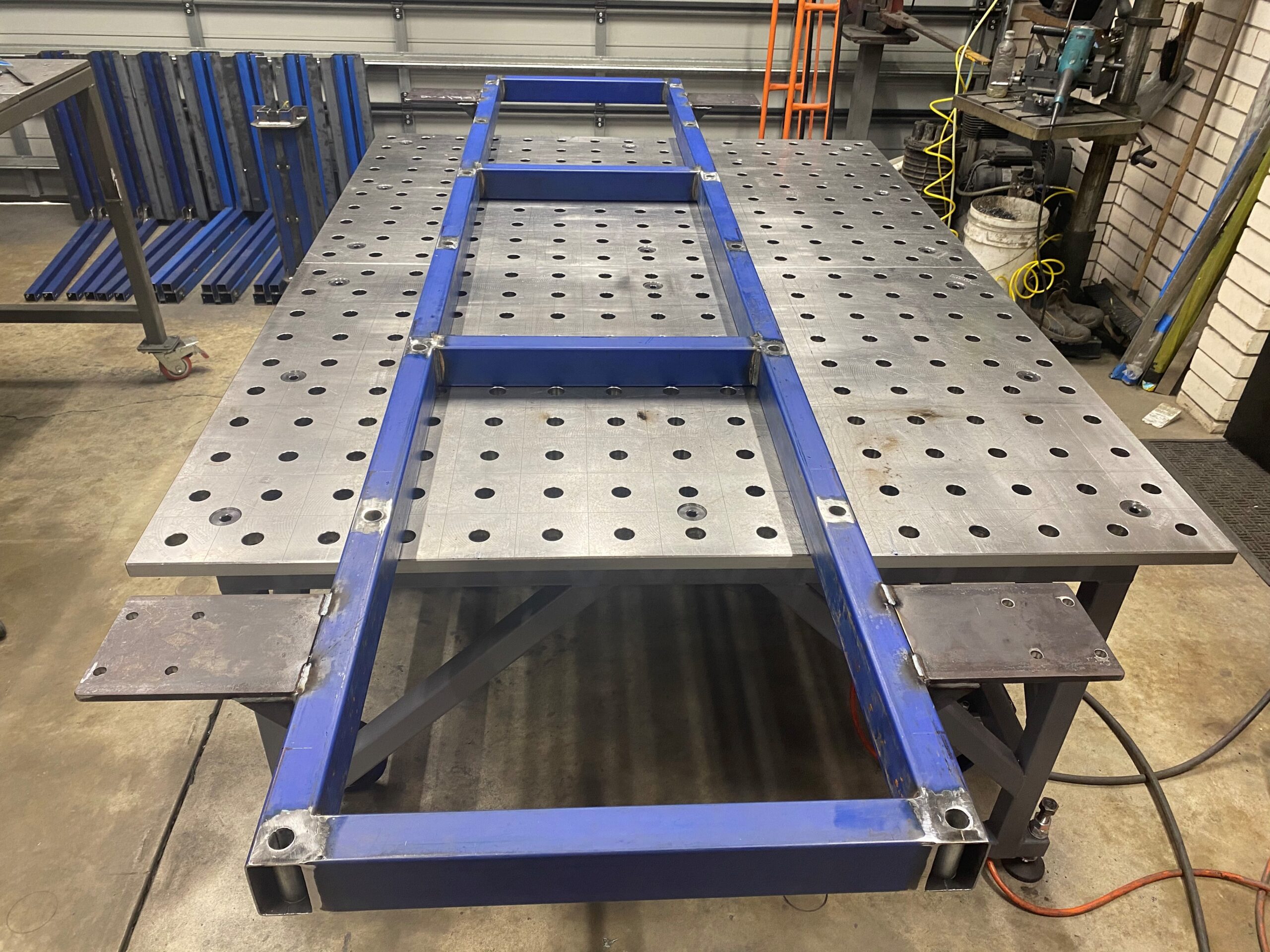

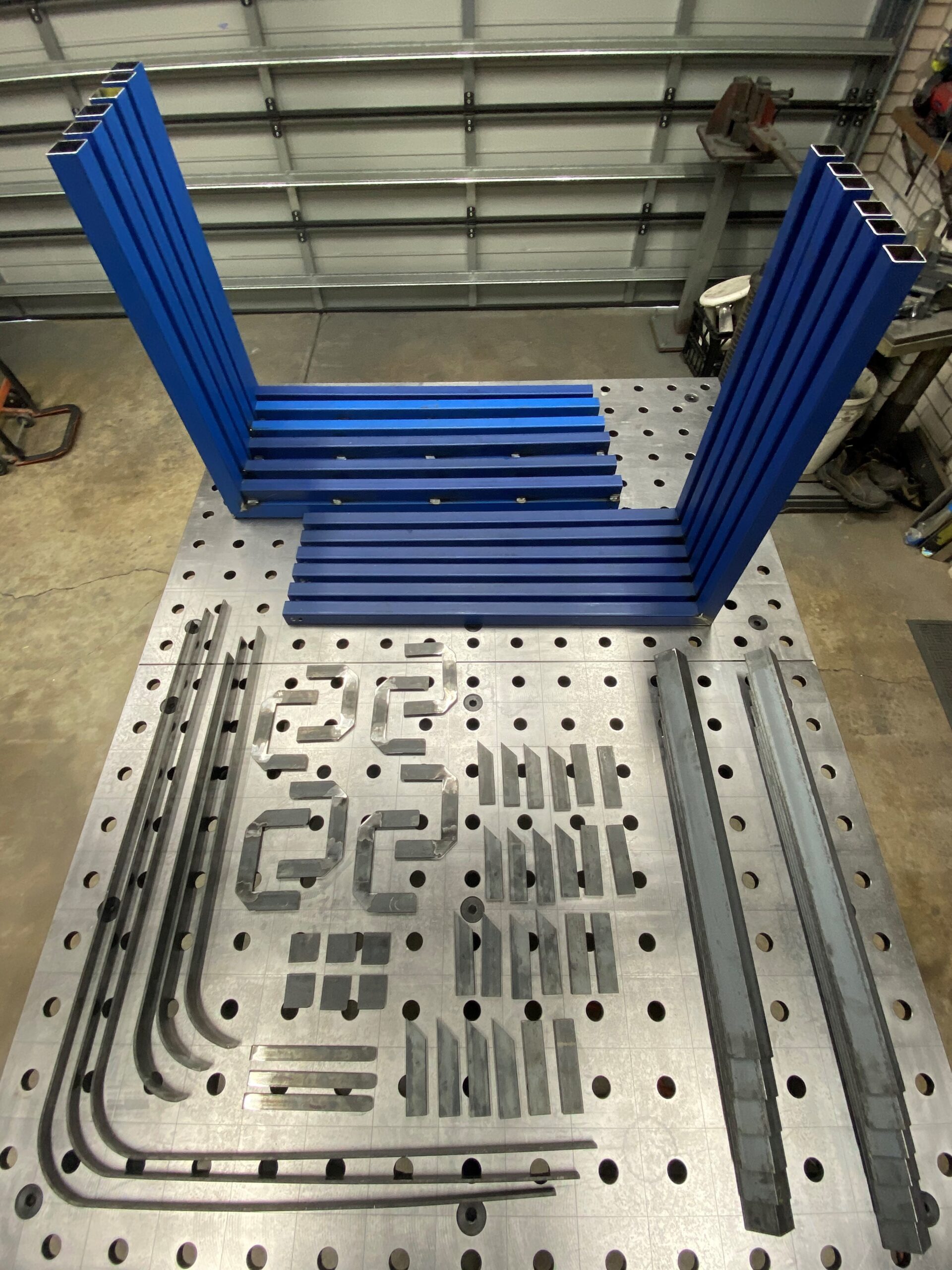

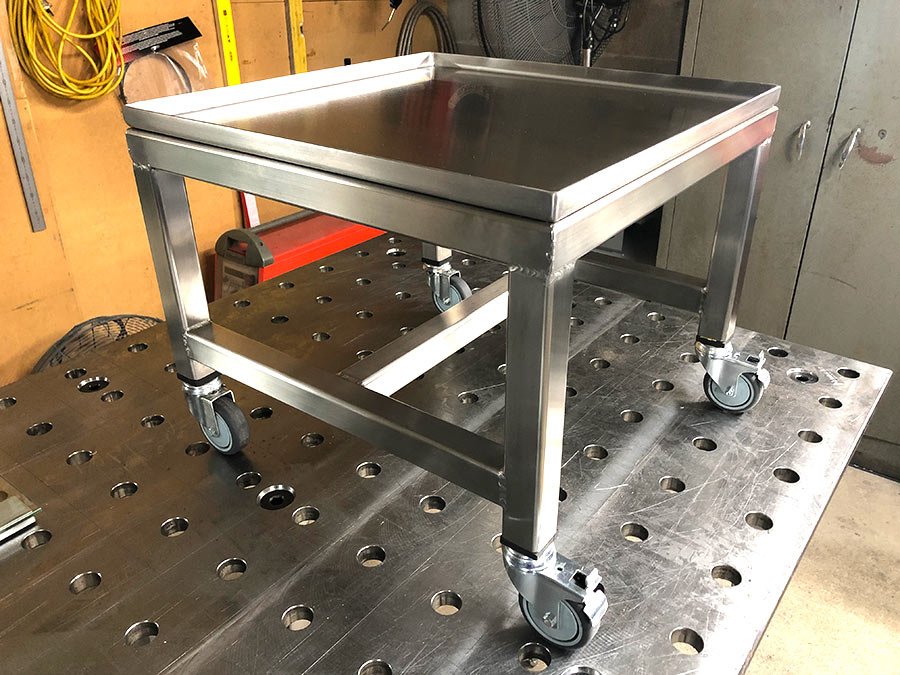

Here is a few photos of some recent projects:

We could never list all the projects we do however, the list will help you further understand our bespoke metal work services:

Every metal fabrication task we do has its own set of unique challenges and problem solving requirements. Below are examples of both projects we have completed and types of projects we like to do

Corten Steel Projects: Cor-ten has become very popular of recent years for is rusty appearance and long weathered life characteristics. It is commonly used for planter boxes, artistic structures, gates, doors and many other outdoor steel projects.

Originally Published here: Blacktown Metal Fabrication Expert. published by MetalmacSunday, 31 January 2021

COR-TEN Steel

Corten is a weathering steel, which is commonly used in projects where painting is not required or not preferred. When exposed to weather, Corten Steel (COR-TEN™) forms a stable rust-like appearance and due to its specific mix of steel alloys, it continues to resist corrosion due to harsh weather conditions for many years.

Corten gets the name ”weathering Steel” due to its ability to form a protective layer on its surface as a result of being exposed to atmospheric conditions. Due to its chemical composition, it is able to resist atmospheric corrosion better than other forms of mild steel.

The protective layer forms as a result of the specific concentration and distribution of the element alloys in it, and the protective surface layer develops and regenerates continuously as the steel forms rust.

With the rising popularity of aged and weathered looking outdoor structures, so too is the popularity of Corten Steel. Also known as ’weathered Steel’, or ’COR-TEN ™’, this very durable material can be used for many different purposes in an outdoor landscape setting. With a number of considerations to take into account that vary from other mild steel projects, Metalmac can produce top quality customised Corten Steel fabrications for any purpose.

Because of its rustic visual appeal, Corten is commonly used for some of the following examples:

| Planter Boxes | Doors | Lighting | Gates |

| Fences | Retaining Walls | Landscape Artwork |

Corten Steel was originally developed in 1933 and patented by the United States Steel Corporation. Not along after this, the developers realised that this steel had unique controlled corrosion properties and applied the trademark name Cor-Ten.

Due to the exceptional mechanical resistance of corten, it was used early on in railroad passenger cars both painted and un-painted, storage containers and for bulk transport purposes.

See Full Article here: COR-TEN Steel. as seen on https://metalmac.com.auSunday, 24 January 2021

Conduit Packaging Jig

Sunday, 25 October 2020

Woodfired Pizza Oven Trailer Installation / Fit Out

Thursday, 13 August 2020

Metal Fabrication

LOOKING FOR AN EXPERT STEEL FABRICATOR?

Customized metal fabrication is a process that involves measuring, cutting, machining and welding any kind of steel materials to specific dimensions, to meet the needs of the customer. A fabricator will usually be called upon to carry out the work because the requirements of the item can not be met through a commercially available or a standard-sized mass-produced item.WORKING WITH A METAL FABRICATOR

As previously mentioned, A metal fabricators role is extremely diverse with each project having its own context and requiring a customised engineering solution. Quite often, It is not only the experience of the fabrication company doing the work but also the ability of its employees to create, design and adapt dynamically.

- Job Requirements

When a customer first meets with a custom metal fabrication expert, they will start by asking a series of questions about the engineering requirements of the project. From here they will consider several different aspects such as dimensions, structural strength and integrity, weight specifications, load specifications, architectural considerations, cost considerations, environmental and any other specific requirements. - Materials

With this information in mind, the fabricator can then decide on the most appropriate material for the role. For example, the product may be intended for use in rust-prone environments meaning high-quality stainless steel may be best suited for the role. In other cases, a cheaper material may be able to replace a more expensive material to meet cost constraints. - Design

After a decision has been made on requirements and materials metal fabricator can then use his creativity and technical knowledge to create a design incorporating all of the required components. When he is satisfied with the design it can then be sent to the client for final approval. - Assembly

Usually the most interesting and rewarding part of a job, the construction phase can include any number of tools and processes including machining, welding, CNC cutting, forming, bending, forging, stamping and many other manufacturing processes.A high-quality end result will be determined by a number of qualities about the individual(s) performing the work including, craftsmanship, attention to detail, equipment used, materials used and time taken.

METAL FABRICATION MATERIALS WE WORK WITH

Below is a list of many of the steels, alloys and other materials we work with.

- Abrasion-resistant plate

- Steel and steel alloys

- Stainless steel

- Galvanized steel

- Carbon steel

- Black Iron

- High-temperature super-alloys

- Nickel and Nickel Alloys

- Aluminium

FAQ

What Does a Metal Fabricator Do?

The role of a metal fabricator is very diverse with just about every job being unique with its own custom requirements, however the role can be defined as follows:

“A Metal Fabricator is responsible for machining, shaping, forming, bending and welding metal to specific dimensions and manufacturing requirements to create custom engineering projects for their customers.

This page Metal Fabrication was initially written by David McNeice for the website www.metalmac.com.au

Metalmac46 Hutchins Cres

Kings Langley NSW 2147

Ph. 0499 499 455

https://maps.google.com/maps?cid=17119035682025509707

Monday, 27 July 2020

Metalmac - Metal Fabrication and Welding in Sydney NSW

Metalmac is a Custom Metal fabrication and Welding Workshop based the the Hills District of North Western Sydney. We specialize in small to mid-sized custom solutions for our clients which includes just about any domestic steel fabrication job as well as equipment, benches, storage and maintenance for larger manufacturing and industrial facilities.

Metalmac owner David McNeice, has had a life long interest in building and creating useful steel structures and designs for himself and his peers. Being the go-to steel fabricator among his friends and colleagues for many years and after becoming tired of a professional career behind a desk, David made the decisions a few years ago to pursue his passion full-time and has been forging a living from steel ever since.

This post first appeared on https://www.metalmac.com.au/

test form

[contact-form-7 id="2378" title="Test form"]Source here: test form . as seen on www.metalmac.com.au

-

[contact-form-7 id="2378" title="Test form"]Source here: test form . as seen on www.metalmac.com.au

-

LOOKING FOR AN EXPERT STEEL FABRICATOR? Customized metal fabrication is a process that involves measuring, cutting, machining and welding an...

-

Metalmac is a Custom Metal fabrication and Welding Workshop based the the Hills District of North Western Sydney. We specialize in small to ...